Add WBUR to your morning routine

After years of starts and stops, Vineyard Wind — the country’s first large-scale offshore wind project — has hit an important milestone: It officially has “steel in the water.” Turbine Wheel

The company has pounded more than a dozen foundations into the ocean floor and is in the process of assembling the first full turbine in the water. When completed, the 62-turbine, 800-megawatt project near Martha’s Vineyard will provide enough carbon-free electricity to power about 400,000 homes in Massachusetts.

Company officials say offshore construction is going a little slower than planned, thanks to inclement weather and rough seas, but that the project is still on track to start sending electricity to shore by the end of the year.

Earlier this year, WBUR visited the site on Cape Cod where the project’s cables will come ashore and connect to the electric grid. Recently, we took another trip to see the onshore staging area at the Marine Commerce Terminal in New Bedford. This specially designed port is where the large turbine parts are stored and partially assembled before being transported to sea.

Offshore wind is still a very new industry in the U.S. And because the country has yet to establish robust domestic manufacturing, all of the major turbine components for the Vineyard Wind project come from overseas.

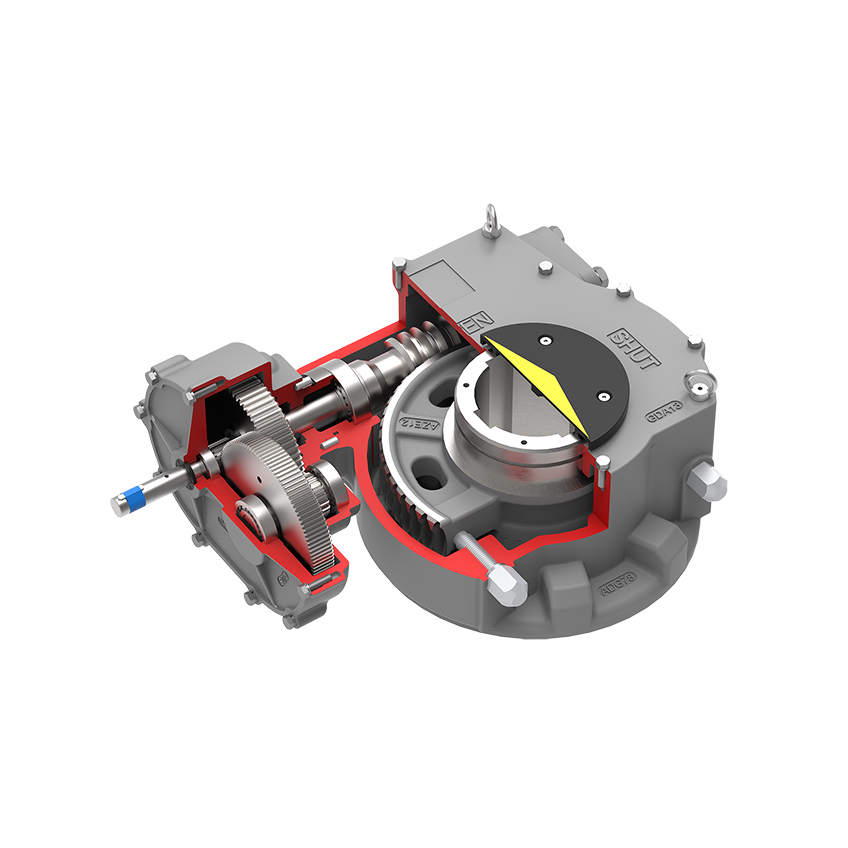

An offshore wind turbine has five big parts: a monopile, which anchors the turbine to the ocean floor; a transition piece, which sticks out of the water and allows maintenance crews to access the turbine; a tower, which gives the turbine its height; a nacelle, which is the "brains" of the turbine and houses all of the power generating components; and three blades, which attach to the nacelle.

In the case of the Vineyard Wind Project, all of these components were manufactured in Europe and Canada and brought to the U.S. on large boats.

The tower portion of a turbine is actually three separate parts that are stacked on top of each other. The first part, T1, is about 104 feet tall. T2 and T3 are each about 130.5 feet tall. Together, they weigh more than 1,000 tons.

The tower sections are made from steel plates that are slowly bent into shape at a manufacturing facility in Portugal. Once they arrive in New Bedford, two sections are assembled onshore with a large crane. The third is placed on top once the bottom portion has been secured to the monopile and transition piece out at sea.

When the blades arrive at the Marine Commerce Terminal in New Bedford, they're arranged in stacks of three — a full set for each turbine. The blades are made from a composite material, and each one is about the length of a football field. Together, the three blades weigh about 192 tons.

Once installed, the Vineyard Wind 1 turbines will be some of the most powerful offshore wind turbines in the world. They are designed and manufactured by General Electric and each one is capable of generating up to 13 megawatts of electricity.

At the top of each turbine tower, construction workers will attach a nacelle, which houses the generator, gearbox, drive shaft and other important components that enable the turbine to create electricity.

Each nacelle in the Vineyard Wind project is about 40 feet tall and weighs 750 tons.

The Foss Prevailing Wind barge, pictured above, is one of only two boats in the world capable of transporting turbine components the size of Vineyard Wind's in an upright position. On Sept. 6, the barge made its first trip from the staging area in New Bedford, through the hurricane barrier and out to the project site in the ocean.

On each trip, the barge can carry 3 blades, 1 nacelle and the two tower parts — enough for one full turbine.

Once the barge reaches the wind lease area near Martha's Vineyard, the turbine components will be transferred to the Sea Installer, a 434-foot long "jack-up vessel." The boat has four 300-foot legs that stand on the ocean floor and allow it rise above the water — this means those on board can work without swaying in the waves.

There are only a handful of jack-up vessels in the world capable of installing turbines this big. The Sea Installer was recently upgraded with a new crane capable of lifting 1,600 tons to accommodate the Vineyard Wind project.

As of late September, the 90 crew members aboard the Sea Installer are working to erect the project's first full turbine. Another vessel, the Orion, is also at the site near Martha's Vineyard. That boat installed the project's 3,000-ton offshore substation and is currently installing more turbine foundations.

Offshore wind projects around the world face financing and supply chain challenges, but clean energy advocates say the progress on the Vineyard Wind 1 project leaves them feeling "cautiously optimistic" about the future of the industry in Massachusetts and the rest of the U.S.

Miriam Wasser Senior Reporter, Climate and Environment Miriam Wasser is a reporter with WBUR's climate and environment team.

Robin Lubbock Videographer, Photographer Robin Lubbock is a videographer and photographer for WBUR.

Worm Gear Actuator Add WBUR to your morning routine